With solid experience behind him at Polestar, among others, Henrik Fries now takes on the role of Senior Director Product Development at ChargeNode. We caught up with him to get an insight into his exciting role.

Henrik Fries joined ChargeNode 3 years ago. He is an electrical engineer from Chalmers, specializing in business administration and entrepreneurship. After graduating, he worked in business and product development in various companies, mostly as an owner. In recent years, he has helped develop Polestar from a pure racing company to offer everything from engine optimizations to Polestar Editions on various Volvo models. When the company was sold to Volvo in 2015, he continued as R&D manager and laid the foundation for Polestar 1 & 2. In other words, the match with ChargeNode’s vision is 100%.

ChargeNode’s journey began with the understanding of two things: First, there must be the ability to charge everywhere in the future. Secondly, the power will be limited, so it is important to distribute the power intelligently. Our customers usually have access to 63-100A in a parking lot and we are unique in being able to operate on such a low current. With centralized energy and charging control, we can ensure that all parking spaces in a facility get the right power at the right time.

All control and intelligence is centralized and distributes power to the right outlets. There can be up to 54 sockets connected to the same charging station. This allows us to make more industrial component choices and easily upgrade and replace parts that wear out. Moreover, the socket installation itself does not take up more space than just one socket. This means that charging sockets can be neatly integrated into the urban environment, for example in our beams and lighting bollards.

In the near future, charging sockets will be as natural as regular wall sockets. But there won’t be unlimited power, so the available power will have to be distributed more intelligently, both at the local level and in society. The next few years will see a tremendous amount of change in terms of hardware, software and services. Which actors survive and do what in the food chain is not obvious. Authorities, energy companies and the automotive industry are also key players in creating the right conditions for charging. I believe we are an important part of this transition from fossil to sustainable. We are relatively young and agile and that will be required in the coming years.

Our philosophy is to always charge each car as soon as possible and not to “smear” the available power. The benefit will be that we can prioritize the charges when the user wants it to be done and how much charge they want. And it only works with a centralized control of all ongoing charges. Our intelligence is centrally located and controls all sockets and charges. This allows us to prioritize and distribute ongoing charges at lightning speed and without the risk of poor communication between different charging stations.

In our next generation of charging systems, which we have just rolled out, we have improved the old architecture mainly in terms of adapting for volume production, logistics and installation. The Gen4 system is smaller and lighter, but still has the same capacity of up to 66kW simultaneous charging. One of the new features is that we can connect anything from 9 to 54 charging points to the same charging station. We continue to charge the optimal number of cars, usually two to six vehicles depending on the available power on the service. We also open up the possibility of using all sockets at the same time, for example for engine heaters. Also in the pipeline is our first proprietary DC charging product and a more modularized charging hardware that will more than halve the installation time.

My cars are a passion, a racing hobby and a job. Long before the Polestar, I experimented with an electrically converted Smart. Now I have a 2-seater Renault Twizzy, which is one of the first electric cars. It is something of a rolling laboratory for both electric motor tuning and DC charging. Of course, I’ve sharpened the software and doubled the power, and now a battery and motor change is in order. For longer rides, however, I use my Polestar 2 Performance.

ChargeNode integrates the payment solution with many leasing companies such as Ziklo Bank, Autoplan, Leaseplan, Bilreda and others.

We can integrate with your own business-critical financial and operational monitoring systems to make charging an integral part of your business with minimal administration.

Advanced troubleshooting and remediation.

If you prefer digital contact with us over the phone – no problem, we offer automated support via our AI bot on the website.

Web-based help center with instructive videos and texts explaining how our portal and app work.

Personalized service around the clock.

Personalized service around the clock.

We offer different levels of service based on your needs.

Collect all your charges on a single invoice with our business account. Convenient for those with pool or staff cars.

Public charging points with a power above 50kW must offer payment with a physical payment terminal. We offer a pre-integrated payment terminal through our partner Adyen – pre-configured with our intuitive interface for selecting charging outlets and charging status.

Want to use your own app? We offer integration with other apps via the industry-standard OCPI protocol.

Pay without an app by scanning the QR code on the charging socket and entering payment card information. Support for ApplePay/GooglePay makes this an easy and attractive option for infrequent shoppers such as passing tourists.

As a charging customer, you always have free access to the ChargeNode mobile app for iOS and Android. Here you can easily activate charging, see a map view of ChargeNode’s public charging points and receive ongoing information about charging status. Here we can also provide information and help with the service. If your company is connected to ChargeNode, you can easily switch between private and business charging. You can also easily charge without the app via an assigned RFID tag.

Charge easily with ApplePay/GooglePay!

Fast, secure and contactless – choose Apple Pay or Google Pay at checkout for an easier payment experience, directly from your mobile.

Export of all session data and history for import into a separate BI tool.

Access to all invoices and invoice specifications as downloadable pdf.

In our portal, you can easily view and update the price for your area. You choose how you want to control pricing – we offer three flexible options:

Fixed price

With a fixed price you set a specific price per kWh including VAT.

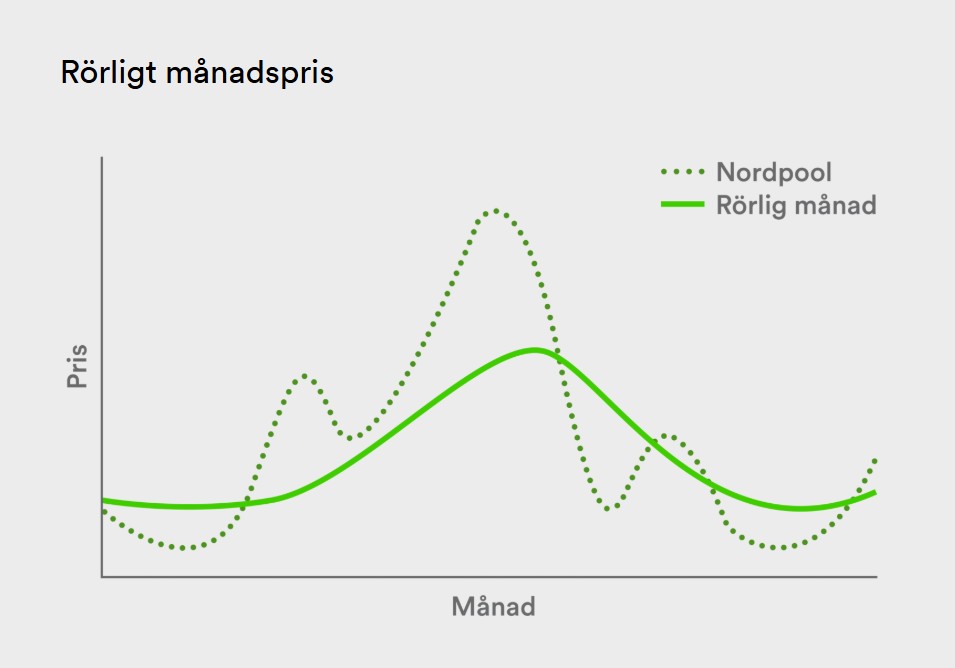

Variable Monthly Price

The Variable Monthly option follows the current Nord Pool price based on the electricity area you belong to.

Scheduled price

Scheduled price allows you to set different prices for different times of the day or different days of the week.

Easily manage who can access your charge points, create member groups and price discounts.

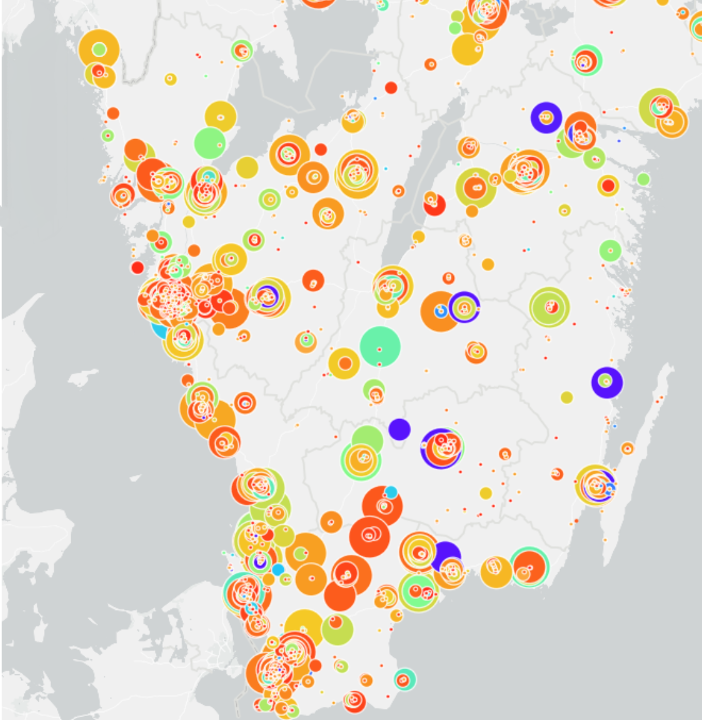

Our powerful dashboard gives you a complete overview of your charging facility – from energy consumption and power peaks to charging patterns and unique users. Visualize user data, identify areas for improvement and make smarter decisions based on real insights.

Connect sockets to a specific user profile to automatically start charging when the cable is plugged in.

Start and stop charging with RFID tag.

Direct connection to Nordpool for loading spot prices (of hourly and quarterly prices). Enables smart pricing models to maximize the profitability of your charging portfolio.

System support to support the loyal network owner or Svenska Kraftnät when needed.

Restart the charge points automatically in case of power failure (Hardware dependent)

Prioritize individual outlets for e.g. mission-critical operations such as pool cars, service cars to ensure that the cars are always prioritized for charging so that operations do not stop. When priority outlets are not active, available power is distributed to other outlets to constantly maximize the charging capacity of the entire system

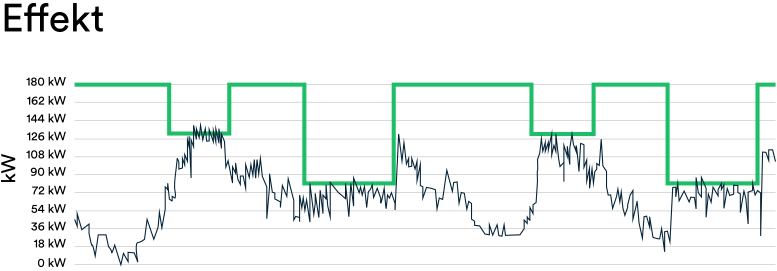

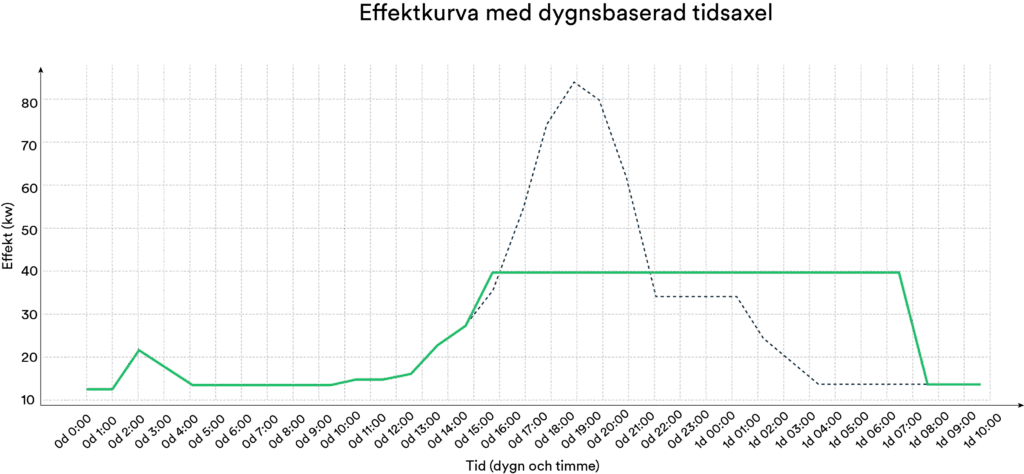

A dynamic power schedule gives you full control over the maximum power of your plant – adapted to the daily load and grid cost. The graph above shows how the schedule (green line) controls available power depending on time, while actual power use (black line) is safely within these limits.

Advantages of the power scheme:

The result: lower costs, more stable operation and more sustainable use of the electricity grid – perfect for homes, businesses and depot charging.

Charging all vehicles at full power at the same time is neither energy efficient nor economically sustainable. By instead prioritizing charging based on the vehicle’s departure time, we can use the available power in a smarter way – without leaving anyone with an empty battery.

Advantages of departure time controlled charging:

This type of dynamic control is particularly suitable for residential, commercial and depot charging – where vehicles are parked for a long time but do not need to be charged immediately.

Our backend load balances all OCPP compliant hardware to protect the property’s main fuse against overload and at the same time maximize the total power available for EV charging. We can load balance statically against a fixed power budget or dynamically, which means that the power budget for charging in real time relates to the property’s power consumption. We support both DLM (Dynamic load management) and ALM (Adaptive Load Management) standards.

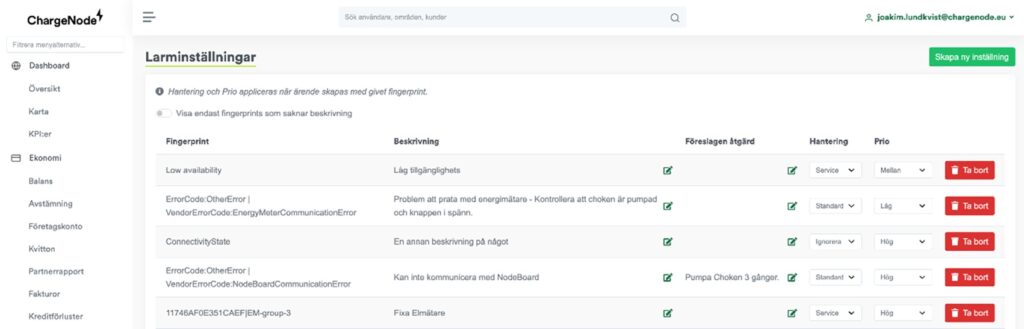

With our intuitive alarm management module, you can keep track of the operational status of your charging infrastructure. It analyzes fault codes, automatically classifies alarms and suggests actions – so you can act quickly and efficiently.

Smarter service starts with the right insights – at the right time.

In addition, you monitor the charging points’ session data, see limits for e.g. uptime, automatically generate alarms and suggest action.

Our backend is integrated with an OCPI-compliant API that enables standardized and secure communication with other e-mobility systems and actors. This makes it easy to exchange data with external platforms – without exposing our entire infrastructure.

Advantages of our OCPI-API:

Our API is the obvious interface to create seamless charging across network boundaries – without compromising control or data security.

ChargeNode handles the payment with the charging customer and reimburses the facility owner via a self-invoice, completely without administration. All you need to do is post the invoice.

We have worked with almost all types of hardware and most brands of charging stations for many years. We have a deep understanding of how they work in operation and this is knowledge that we bring to every meeting and every decision. We have also developed our own hardware which, to put it mildly, is probably the best on the market.

Er anläggning driftsätts i vår portal och ni får tillgång till er kundportal. Vårt Customer Success-team står redo att erbjuda utbildning i portalen om så önskas. Under hela avtalstiden garanterar vi laddkunder support 24/7, 365 dagar om året. Vi är alltid tillgängliga via telefon för att hjälpa.

Vi har jobbat med nästan alla typer av hårdvara och de flesta märken på laddboxar i många år. Vi har en djup förståelse för hur de funkar i drift och detta är kunskap som vi tar med oss i varje möte och varje beslut. Vi har dessutom utvecklat en egen hårdvara som, om man ska sticka ut hakan lite, troligtvis är den bästa på marknaden.